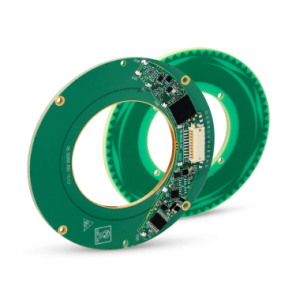

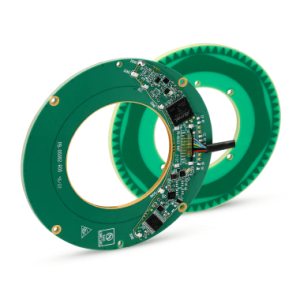

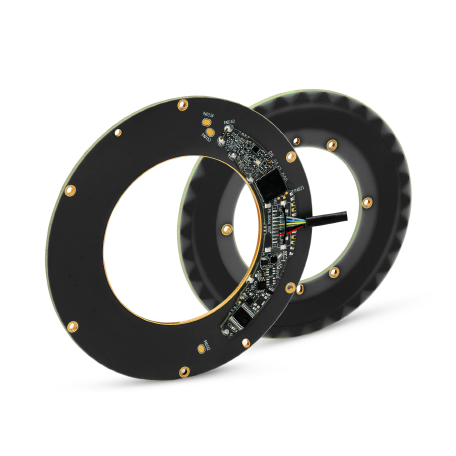

VLS-100 | ABSOLUTE ROTARY ENCODER Hollow Shaft | Kit Encoder

Related Videos

Applications

Features

- High precision and low profile

- Low power consumption

- Space proven performance

- Low outgassing

- Vacuum environment: 10-5 Torr

- Polyimide substrate

- Parylene conformal coating

- Innovative hollow shaft design

- Extreme temperature durability

- Rigorous testing & production: vibration and ESS, thermal vacuum and shock optional

OD

100 mm

ID

48 mm

Height

7 mm

Weight

42 gr

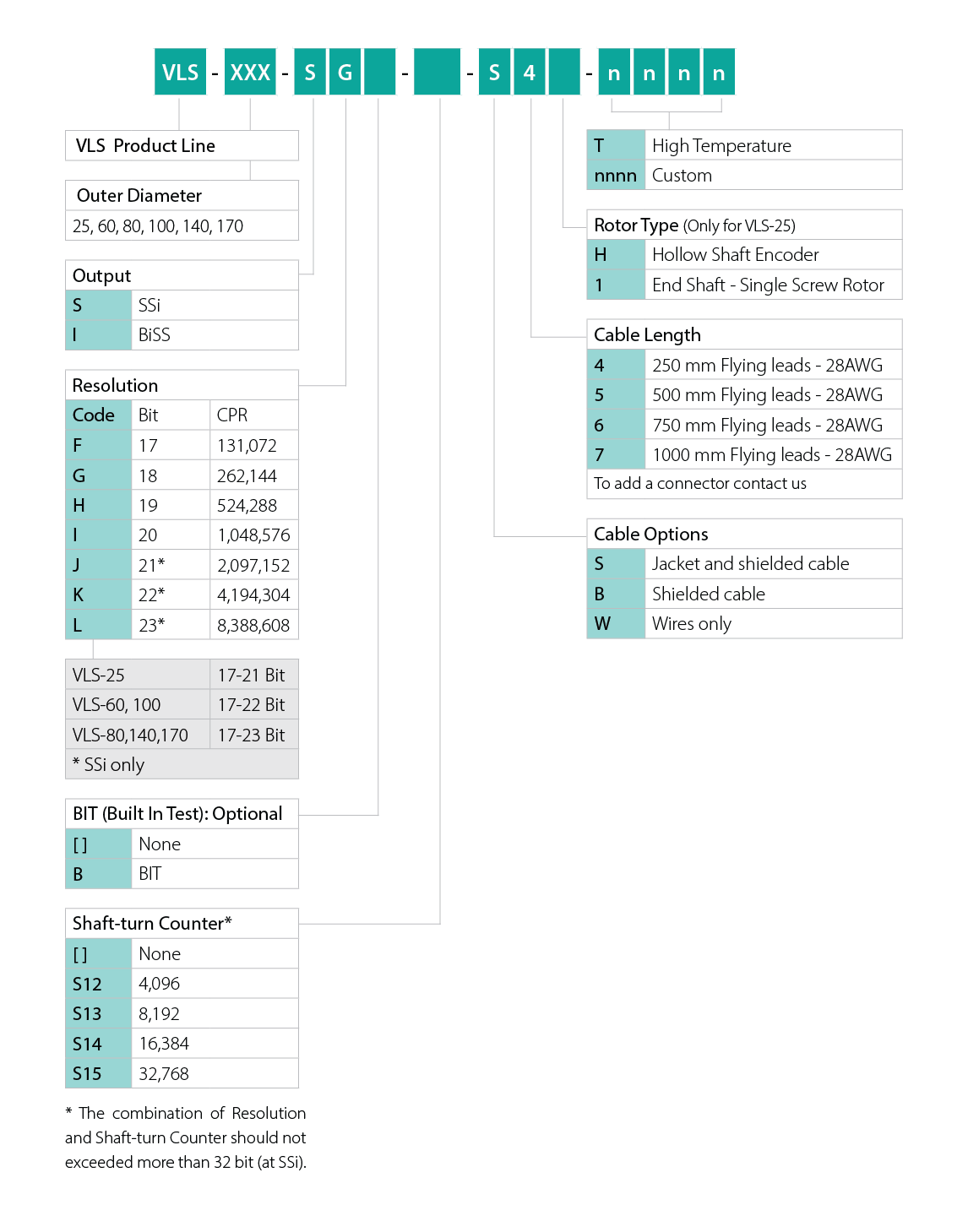

Resolution

17-22 bit

Accuracy

±0.006°

-

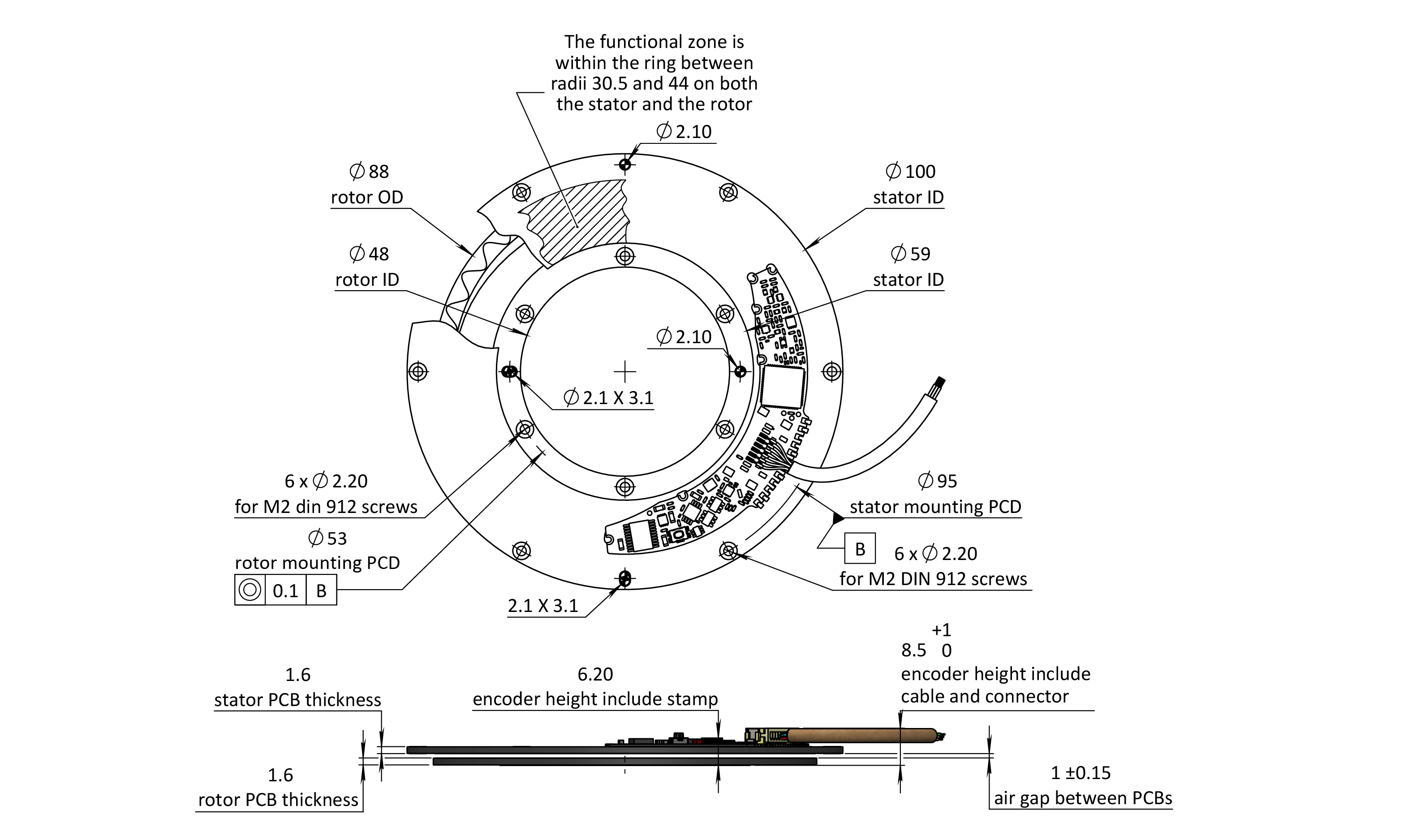

Technical Drawing

-

General

Angular resolution17-22 bitNominal position accuracy±0.006°Repeatability0.7 mdeg / 2.5 ArcsecMaximum operational speed4,000 rpmMeasurement rangeSingle-turn, unlimited. Software Shaft-turnBuilt In Test BITOptionalRotation directionAdjustable CW/CCW (Default same direction from bottom side of the encoder) -

Mechanical

Allowable mounting eccentricity±0.15 mmAllowable axial mounting tolerance±0.15 mmRotor inertia17,928 gr · mm²Total weight42 grOuter Ø /Inner Ø / Height100 / 48 / 7 mmMaterial (stator / rotor)PolyimideNominal air gap (stator, rotor)1 mm -

Electrical

Supply voltage5V ±5%Current consumption~90 mAInterconnectionCable (standard 250mm)CommunicationSSi / BiSS-COutput codeBinarySerial outputDifferential RS-422Clock frequency0.1- 5.0 MHzPosition update rate35 kHz (Optional - up to 375 kHz) -

Environmental

EMCIEC 6100-6-2, IEC 6100-6-4Operating temperature range-40°C to +105°C (Optional +125°C)Storage temperature-55°C to +125°CRelative humidity98% Non condensingShock endurance / functional100g 6msec saw-tooth per IEC 60068-2-27:2009 40g 11msec saw-tooth per MIL-810GVibration functional7.7grms @ 20 to 2000 Hz per MIL-810G Category 24ProtectionParylene conformal coating: improved low outgassing, reduces Tin Whiskers risk.Low out-gassingTML < 1%, CVCM < 0.1%Radiation tested forTID = 30KRAD. SEE 1E11 p/cm²/s protons @200MeV

Order Now