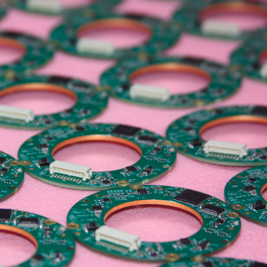

Netzer’s Electric Encoder

Netzer’s electric encoders are designed to provide position sensors that offer the highest levels of accuracy under severe environmental conditions while maintaining the smallest possible footprint and relaxed installation tolerances.

Netzer’s electric encoders provide superior performance when compared to alternative technologies.

- Magnetic sensors suffer from reduced accuracy to size ratio, especially when significant magnetic & electromagnetic (EMC) interference is present.

- Optical sensors provide improved accuracy, but their performance degrades under harsh environmental conditions and they require a very high degree of installation accuracy.

- Netzer developed the electric encoder to overcome these limitations. Netzer’s rotary encoders measure capacitance, which can withstand high levels of EMI and RFI interference. The encoders are immune to additional environmental conditions, such as shocks, vibration, extreme temperatures, and high humidity.

The patented Electric Encoder technology measures capacitance in a “holistic” manner, combining readings from the entire area of the encoder to ensure high performance and reliability at a relaxed installation tolerance.

The Electric Encoder uses fewer components than the alternative technologies, offering the following additional benefits:

- A smaller footprint requires less surface area, easing integration into complex systems.

- Frame-less design for minimal volume and weight with the highest mechanical reliability.

- Supports an extra-wide hollow shaft with an improved ID/OD ratio.

- Cost savings due to the reduced mechanical requirements and structure.

- Lower profile and lightweight—for simplified system integration.

Thanks to its holistic measuring technique, the Electric Encoder supports relaxed installation tolerances and maintains its outstanding performance under the challenging conditions that are prevalent in aerospace, defense, and industrial applications.

The Electric Encoder is a “smart” sensor. Its integrated CPU and memory allow for zero-position assignment, built-in test functionality, and storage of information for systems with no intrinsic data capabilities. The sensor is highly programmable and allows for the development of innovative new applications and features.

Do you want to know which absolute rotary encoder best suits your application? Contact our engineers for further information.