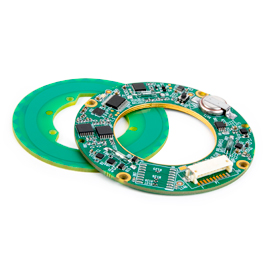

Hollow Shaft Incremental Encoder

Why a Hollow Shaft Incremental Rotary Encoder is a Lot More Versatile Than Solid Shaft Encoders

Hollow shaft encoders can be absolute or incremental. They come in different sizes and resolutions. They are easy to install, unlike shafted encoders and they do not require coupling or motor shaft alignment. Hollow shaft incremental encoders are typically used in positioning as well as in motor speed feedback applications. These can be servo/light and industrial or heavy-duty applications. A hollow shaft incremental rotary encoder is able to provide excellent velocity feedback.

Incremental shaft encoders are limited because they only provide angular increments. That means the encoder would need a reference device so it can determine the absolute angular position and an initialization procedure – called homing. Some of the applications where incremental rotary encoders can be used include cut-to-length, crane, or hoist, and it can also be used in heavy vehicle applications.

In comparison, absolute encoders are used in determining the speed or position of something. How the encoder determines the movement will determine what type of encoder will work best in specific applications. Absolute encoders work best in situations when homing is not practical. When a high resolution is required, absolute encoders can also be used such as in medical and robot applications, CNC, etc…

Compared to solid shaft encoders, a hollow shaft rotary encoder is a lot more versatile. It is one of the most commonly used designs. Instead of a solid mechanical shaft that needs to be coupled to the motor, a hollow shaft rotary encoder fits over the motor or other system shaft and is then clamped into place. That means, it doesn’t need to be the perfect size to fit the motor and it doesn’t need flexible coupling components to adapt inherent mechanical mounting tolerances that otherwise would occupy space and increase size. Another advantage of hollow Shaft Encoders is that they have a more forgiving installation. Aside from saving space hollow shaft encoders eliminate shock-induced deformations on mechanical shaft couplers which otherwise would cause non-repeatable angular reading.

Do you want to know which absolute rotary encoder best suits your application? Contact our engineers for further information.